Aluminum railings are a popular choice for residential […]

Aluminum railings are a popular choice for residential and commercial properties due to their strength, durability, and aesthetic appeal. Whether used for decks, balconies, staircases, or fences, aluminum railings offer a modern and low-maintenance alternative to other materials such as wood or wrought iron. The production process of aluminum railings involves several precise steps to ensure high-quality, durable, and visually appealing products.

1. Material Selection and Preparation

The step in the aluminum railing production process is selecting the right type of aluminum. Many aluminum railings are made from aluminum alloys, typically alloy 6063, which is known for its excellent corrosion resistance, good strength, and ability to withstand weather conditions.

Once the aluminum alloy is chosen, the raw materials are sourced in the form of aluminum extrusions, which are long pieces of metal with a consistent profile. These extrusions serve as the main structural components of the railing system, such as posts, top rails, and balusters.

Before starting the manufacturing process, the aluminum extrusions are inspected to ensure they meet quality standards. Any defects or imperfections in the material are addressed before moving forward to avoid compromising the strength or appearance of the final product.

2. Extrusion Process

Extrusion is a key step in the production of aluminum railings. In this process, aluminum is heated until it reaches a malleable state and then forced through a die to create the desired profile or shape. This die shapes the aluminum into various components, such as vertical posts, horizontal rails, and decorative elements.

The extrusion process is highly efficient, allowing manufacturers to produce large quantities of aluminum railing components with consistent quality. It also offers flexibility in terms of design, as different shapes and sizes can be created based on customer specifications. The extruded aluminum pieces are then cooled and cut to the required lengths.

3. Cutting and Shaping

Once the aluminum extrusions have been produced, the next step is cutting them into the required lengths and shapes. This involves using high-precision machinery such as saws or cutting machines to ensure that each piece of aluminum is cut accurately according to the design specifications.

Some components, such as posts and rails, may require additional shaping or modifications, such as holes for screws or connectors. These are also achieved using advanced cutting and drilling machines, which ensure that the pieces are prepared for assembly and installation.

Additionally, any decorative elements, such as scrolls or custom designs, may be added at this stage, depending on the customer’s preferences.

4. Surface Treatment

The surface treatment of aluminum railing components is crucial for enhancing durability and appearance. Aluminum naturally forms a protective oxide layer, but additional treatments are often applied to ensure further protection against corrosion, UV damage, and wear over time.

The common surface treatment for aluminum railings is anodizing, a process in which aluminum is electrochemically treated to create a thick oxide layer. This oxide layer not only protects the aluminum from corrosion but also improves the material's ability to withstand weathering, scratches, and fading.

In addition to anodizing, some aluminum railings may undergo a powder coating process. Powder coating involves applying a dry powder to the surface of the aluminum, which is then cured with heat to form a smooth, durable finish. Powder coating provides a wide range of color options, allowing customers to choose from various hues to match the aesthetic of their property.

Other surface treatments, such as polishing or brushing, may also be applied to achieve different textures or finishes, depending on the desired look.

5. Assembly

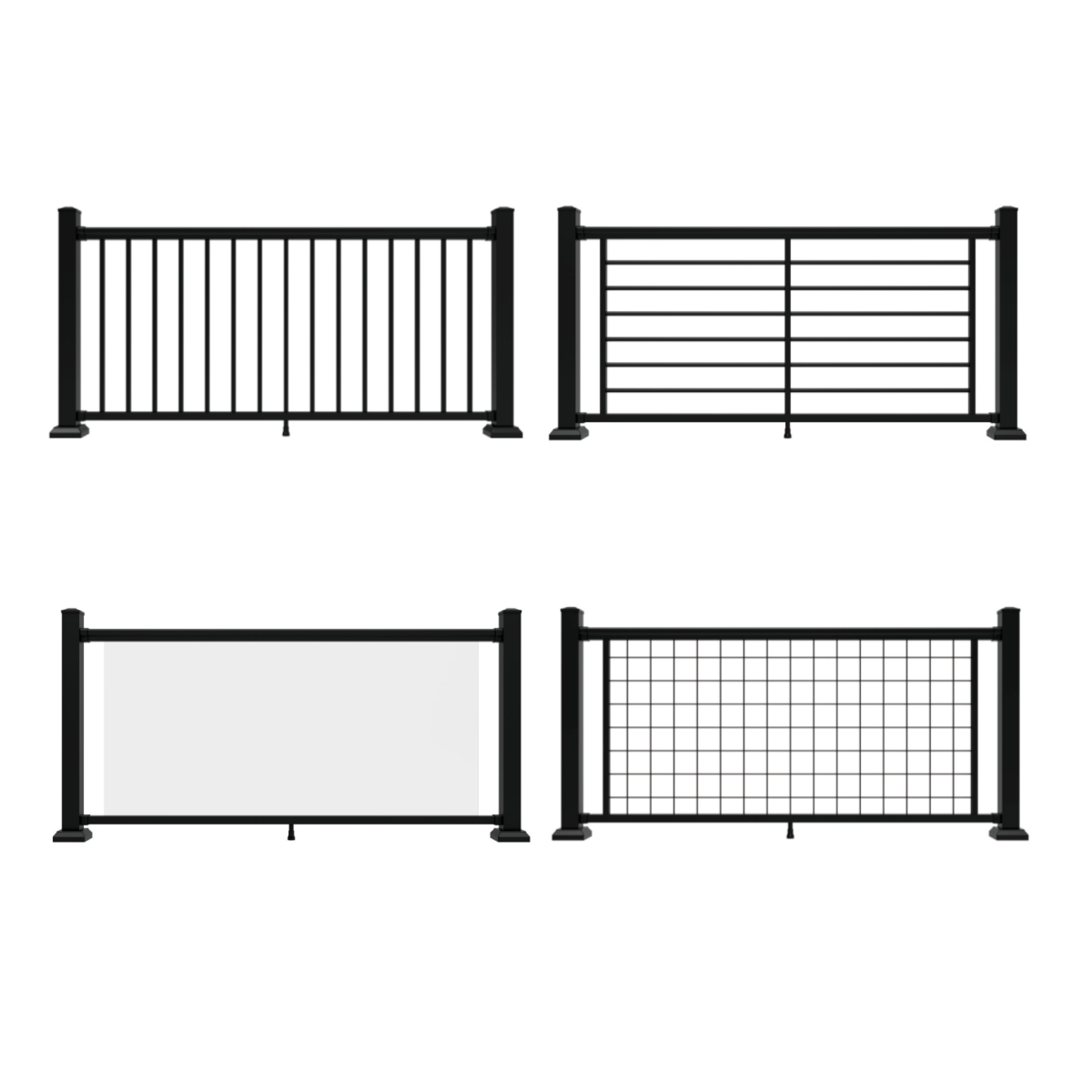

Once the aluminum components have been cut, shaped, and treated, they are ready for assembly. The assembly process involves joining the different parts of the railing system, such as posts, rails, and balusters, into a cohesive unit.

There are several methods of assembly, depending on the design of the railing system. In cases, the components are secured using screws, bolts, or brackets. For added stability and strength, some aluminum railings may feature hidden fasteners or special connectors that are designed to minimize visible hardware.

If the railing design includes glass panels or other materials, these elements are also integrated into the structure at this stage. The assembly process is highly precise, as each piece must be aligned and secured properly to ensure both functionality and aesthetics.