Aluminum railings have become a popular choice in both […]

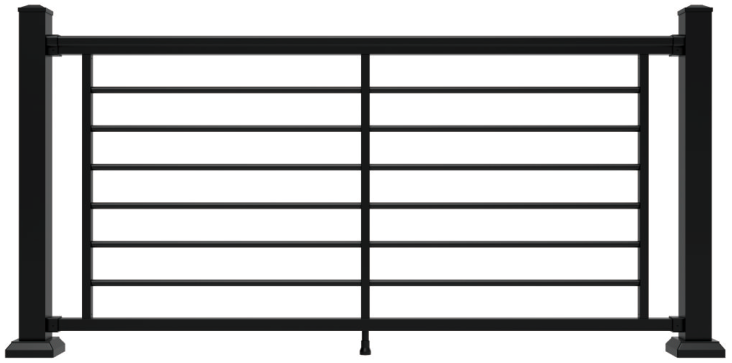

Aluminum railings have become a popular choice in both residential and commercial construction due to their strength, lightweight properties, corrosion resistance, and aesthetic flexibility. Whether used for balconies, stairways, porches, or decking, aluminum railings are expected to deliver long-term durability and reliable safety. However, like any manufactured product, aluminum railings are subject to potential defects arising during the production process. These defects can affect functionality, appearance, and compliance with safety standards. Understanding the factors that influence the production defect rate is important for manufacturers aiming to maintain consistent product quality and for consumers interested in purchasing high-performing, defect-free railings.

The foundation of a high-quality aluminum railing system begins with the raw materials. Aluminum alloys used in railing production must meet strict compositional and structural requirements to ensure strength and corrosion resistance.

Alloy Composition: The grade and composition of aluminum (e.g., 6061 or 6063 alloys) influence the railing's mechanical performance. Inconsistent alloy content can bring about variations in strength and susceptibility to corrosion.

Material Purity: Impurities such as iron or silicon in excess amounts may introduce brittleness or surface defects.

Supplier Variability: Sourcing aluminum from multiple suppliers without standardized testing protocols may result in inconsistent batches, increasing the likelihood of defects.

Recommendation: Establish supplier qualification systems and perform incoming quality control checks on aluminum billets or extrusions.

Aluminum railing components are often manufactured through an extrusion process, where heated aluminum billets are forced through a shaped die to form consistent profiles. The quality of the extrusion process plays a vital role in reduce production defects.

Die Quality and Maintenance: Worn or damaged dies can produce inaccurate dimensions or surface imperfections such as drag lines or die marks.

Temperature Control: Inconsistent heating can cause uneven flow, bring about warping or internal stress points.

Speed and Pressure: Improper control of extrusion speed or pressure may bring about cracks, dimensional inaccuracies, or non-uniform finishes.

Recommendation: Monitor and calibrate extrusion parameters regularly and perform routine die maintenance to ensure profile consistency.

Many aluminum railings undergo additional surface treatments such as anodizing or powder coating for corrosion resistance and aesthetic enhancement. However, this stage introduces its own set of potential defects.

Anodizing Defects: Inconsistencies in the anodizing bath can bring about discoloration, uneven coating thickness, or poor adhesion.

Powder Coating Issues: Defects such as orange peel texture, bubbling, or peeling may occur due to improper pre-treatment, humidity, or incorrect oven curing cycles.

Surface Contamination: Residues from oils, dust, or previous processing stages can interfere with coating adhesion or appearance.

Recommendation: Implement rigorous pre-treatment cleaning protocols and maintain tight control over coating environments.

After extrusion and surface finishing, aluminum railing components are typically cut, drilled, and assembled into final products. Mistakes during fabrication or assembly can introduce a variety of functional or visual defects.

Dimensional Inaccuracies: Incorrect cutting or drilling can bring about parts that do not align or fit properly.

Poor Welding or Fastening: Weak joints due to improper welding techniques or inadequate fasteners can compromise safety and durability.

Mismatched Components: Using incorrect or off-spec parts during assembly can affect both strength and aesthetics.

Recommendation: Use precision machinery and jigs during fabrication, and verify component compatibility at each stage of assembly.