When considering safety and style for a deck, balcony, […]

When considering safety and style for a deck, balcony, or staircase, railing is a fundamental component. It provides a necessary barrier while also significantly influencing the overall aesthetic of a space. Among the various materials available, aluminum has become a prominent choice for homeowners, architects, and builders. Its appeal lies in a combination of durability, low maintenance, and design flexibility. Exploring the options for modern aluminum railing reveals a product category that is far from one-size-fits-all. The choices available allow for significant customization, ensuring that the final installation can complement any architectural style, from minimalist and contemporary to more traditional looks. The primary areas of variation can be found in the style and infill designs, the finish and color options, and the specific type of aluminum used in construction.

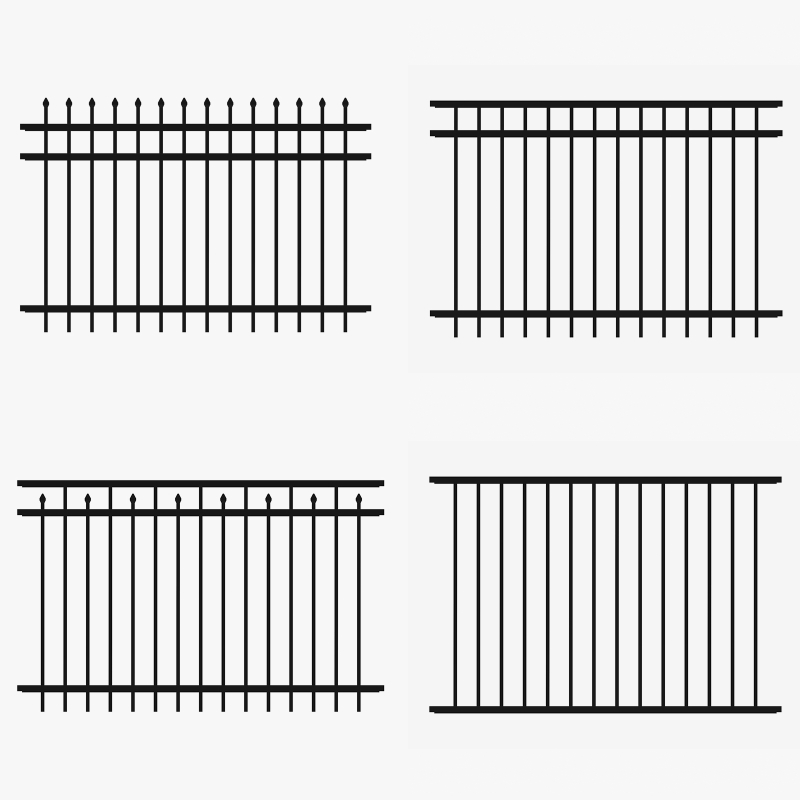

Style and Infill Design Variations

The most visible aspect of any railing is its design, which is largely defined by the configuration of its posts and the infill material between them. This is where the aesthetic character of the modern aluminum railing is established.

Horizontal Cable Railings: This style utilizes thin, taut horizontal cables running between posts. It offers a very clean, unobstructed view, making it ideal for properties with scenic vistas. The sleek lines contribute to a distinctly contemporary look that emphasizes openness and space.

Glass Panel Infills: For a truly seamless view and a sophisticated appearance, tempered glass panels are a popular option. A modern aluminum railing with glass infills creates a transparent barrier that provides safety without visual interruption. This style is common in urban settings and for properties where maximizing light and view is a priority.

Traditional Baluster Designs: For those who prefer a more classic appearance, aluminum can be formed into balusters that mimic the look of traditional wrought iron. These can be simple, vertical rods or feature more elaborate scrollwork. This design offers a timeless look but with the benefit of aluminum’s lightweight and rust-resistant properties.

The choice of infill directly impacts the feeling of openness, the level of maintenance, and the overall architectural integration of the railing system.

Finish and Color Options

Beyond the structural design, the visual impact of a railing is determined by its finish. The manufacturing processes for aluminum allow for a wide range of colors and textures, enabling the railing to either blend in with its surroundings or stand out as an accent feature.

Anodized Finishes: Anodizing is an electrochemical process that thickens the natural oxide layer on the aluminum, creating a very hard, durable, and corrosion-resistant surface. This typically results in muted, metallic shades like clear (silver), bronze, and black. An anodized finish is integrated into the metal itself, making it highly resistant to chipping and fading.

Powder-Coated Finishes: Powder coating is the most common method for adding color to a modern aluminum railing. A dry powder is applied electrostatically and then cured under heat to form a solid, protective skin. This process offers an almost limitless color palette, from classic black and white to custom-matched hues. A high-quality powder coat provides excellent resistance to scratching, chipping, and UV damage, ensuring the color remains vibrant for years.

The selection of a finish is a critical step in personalizing the railing and ensuring it coordinates with other elements like window frames, siding, or outdoor furniture.

Material and Construction Types

The term "aluminum railing" can refer to different forms of the metal and methods of assembly, which affect the installation process, strength, and final appearance.

Extruded Aluminum Systems: Many modern aluminum railing products are made from extruded aluminum. This process involves forcing heated aluminum through a shaped die to create long pieces with consistent, complex cross-sectional profiles. These systems are often modular, designed for straightforward assembly with pre-drilled holes and standardized components, which can be advantageous for DIY projects or efficient professional installation.

Structural and Fabricated Aluminum: For more custom or heavy-duty applications, aluminum can be used in structural forms, such as square or rectangular tubing. These systems are often welded and fabricated by skilled metalworkers to create unique designs. This approach allows for greater customization in terms of post size, unique angles, and integrated features, resulting in a one-of-a-kind modern aluminum railing.