The primary role of any railing system is to provide sa […]

The primary role of any railing system is to provide safety, and aluminum railing fulfills this role efficiently. Whether installed on balconies, staircases, ramps, or elevated platforms, aluminum railing acts as a physical barrier to prevent accidental falls. As manufacturers, we design and test aluminum railing systems to meet industry safety standards, including those set by building codes and regulatory authorities.

Due to its structural strength and corrosion resistance, aluminum railing performs well even in outdoor or high-traffic environments. Properly engineered aluminum railing systems offer sufficient load-bearing capacity while remaining lightweight, making them easy to install without compromising safety.

Durability in Diverse Environments

One of the significant advantages of aluminum railing is its durability. Aluminum as a base material does not rust, making it suitable for a range of environmental conditions, including coastal areas, industrial zones, and places with significant moisture exposure. As a manufacturer, we frequently apply powder coating or anodizing processes to enhance surface protection and prolong the service life of our aluminum railing products.

Unlike some materials that deteriorate quickly when exposed to changing weather, aluminum railing retains its structural integrity and appearance with minimal maintenance. This durability contributes to long-term cost savings for property owners and reduces the frequency of replacement or repairs.

Aesthetic Flexibility and Design Options

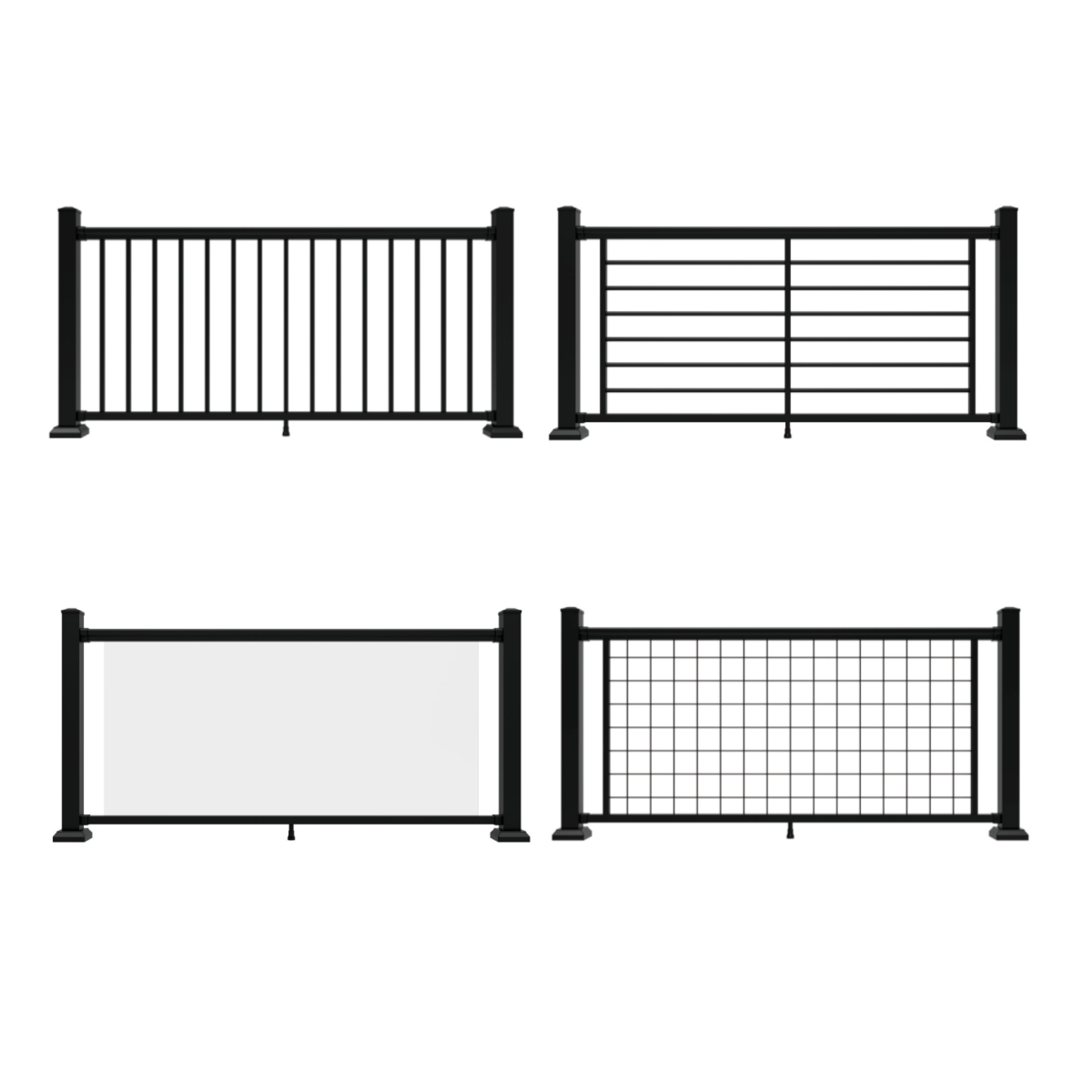

Beyond functionality, aluminum railing contributes significantly to the visual appeal of a structure. Architects and designers often choose aluminum railing for its clean lines, modern look, and adaptability to different styles. As manufacturers, we offer a variety of profiles, colors, and finishes that complement both contemporary and traditional design themes.

Whether the project calls for sleek horizontal lines, decorative panels, or glass inserts combined with metal framing, aluminum railing systems offer the flexibility to achieve diverse design objectives. This versatility makes it suitable for residential, commercial, and institutional applications alike.

Ease of Installation and Customization

From a production standpoint, aluminum railing systems are typically prefabricated for easy assembly and installation. The components are designed for modular use, allowing for customization based on the project's requirements. This simplifies the work of contractors and builders, reducing on-site fabrication time and the potential for installation errors.

We often work with architects, contractors, and property developers to deliver custom aluminum railing solutions tailored to unique site specifications. The ability to produce exact lengths, custom angles, and specific mounting systems gives aluminum railing an advantage over some traditional materials.

Low Maintenance Requirements

Another key role that aluminum railing plays is reducing the maintenance burden for end-users. Unlike wood or wrought iron, aluminum railing does not require frequent painting, staining, or treatment to preserve its appearance or function. The baked-on finishes we apply in the manufacturing process help resist fading, chipping, and corrosion over time.

This characteristic is particularly appealing for large-scale developments like apartment complexes, hotels, or public facilities, where maintaining multiple railing systems could otherwise become a significant ongoing expense. Aluminum railing offers a low-maintenance alternative without compromising on aesthetics or safety.

Environmental Considerations and Recyclability

In recent years, the construction industry has become increasingly focused on sustainability. Aluminum railing, as a recyclable product, aligns with environmentally responsible building practices. The aluminum used in our railing systems is often sourced from recycled materials, and at the end of its service life, the railing itself can be recycled again.